ReductStore v1.18.0 Released with Resilient Deployments and the Multi-entry API

We are pleased to announce the release of the latest minor version of ReductStore, 1.18.0. ReductStore is a high-performance storage and streaming solution designed for storing and managing large volumes of historical data.

To download the latest released version, please visit our Download Page.

What's new in 1.18.0?

In this release, we have added support for resilient deployments to build a more robust, fault-tolerant, and highly available ReductStore cluster. Now, you can implement hot-standby configurations, automatic failover, and seamless recovery to ensure uninterrupted service even in the face of hardware failures or network issues. You can also elastically scale read-only nodes to handle increased read workloads without impacting the performance of the primary nodes.

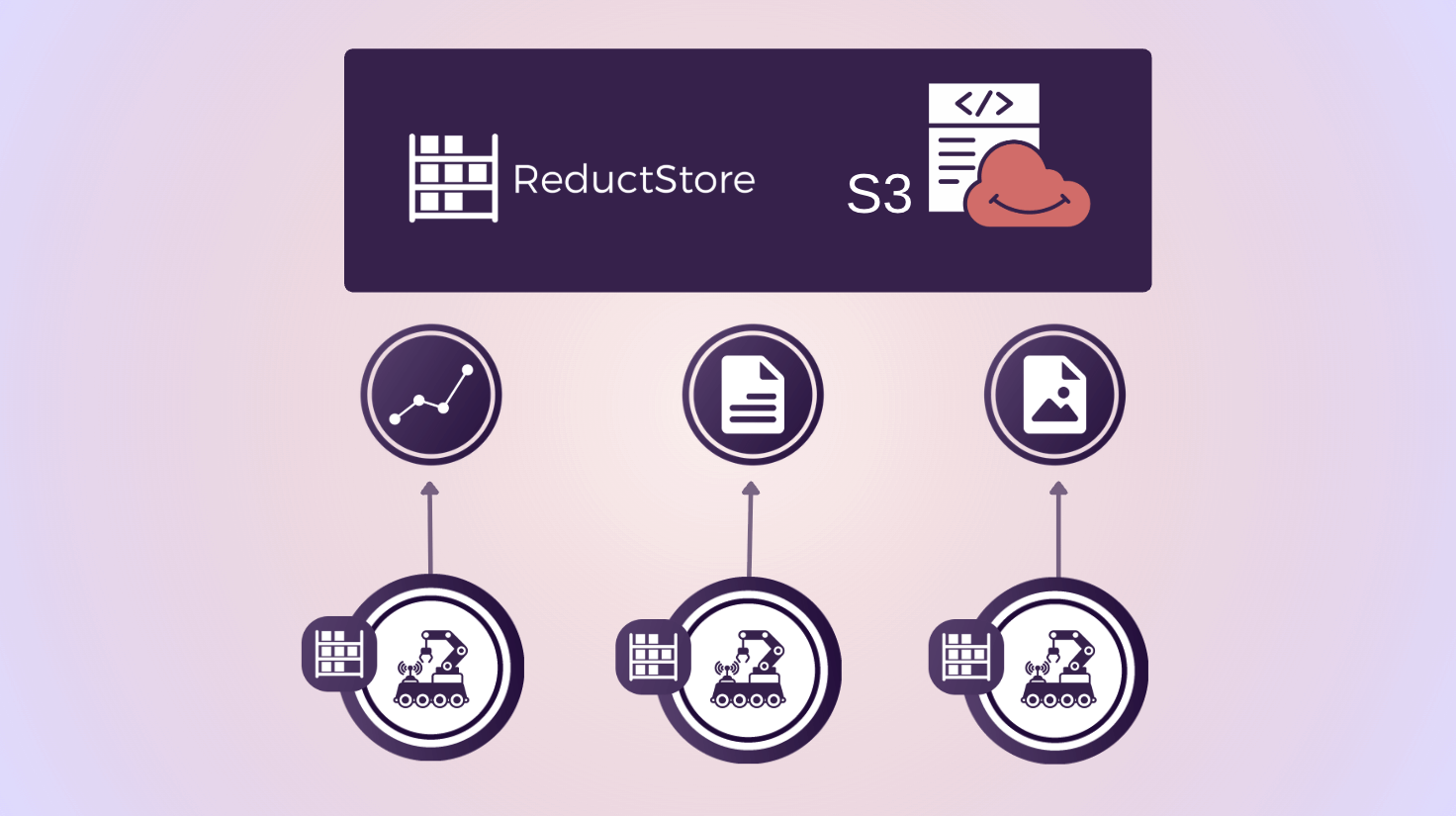

Additionally, we have introduced a new Multi-entry API that allows you to efficiently manage and query multiple entries in a single request. This API is designed to optimize performance and reduce latency when working with large datasets, making it easier to retrieve and manipulate data in bulk.