Building a Data Acquisition System for Manufacturing

Large manufacturing plants generate vast amounts of data from machines and sensors. This data is valuable for monitoring machine health, predicting failures, and optimizing production. It also serves as a foundation for building industrial AI models for predictive maintenance, quality control, and process optimization.

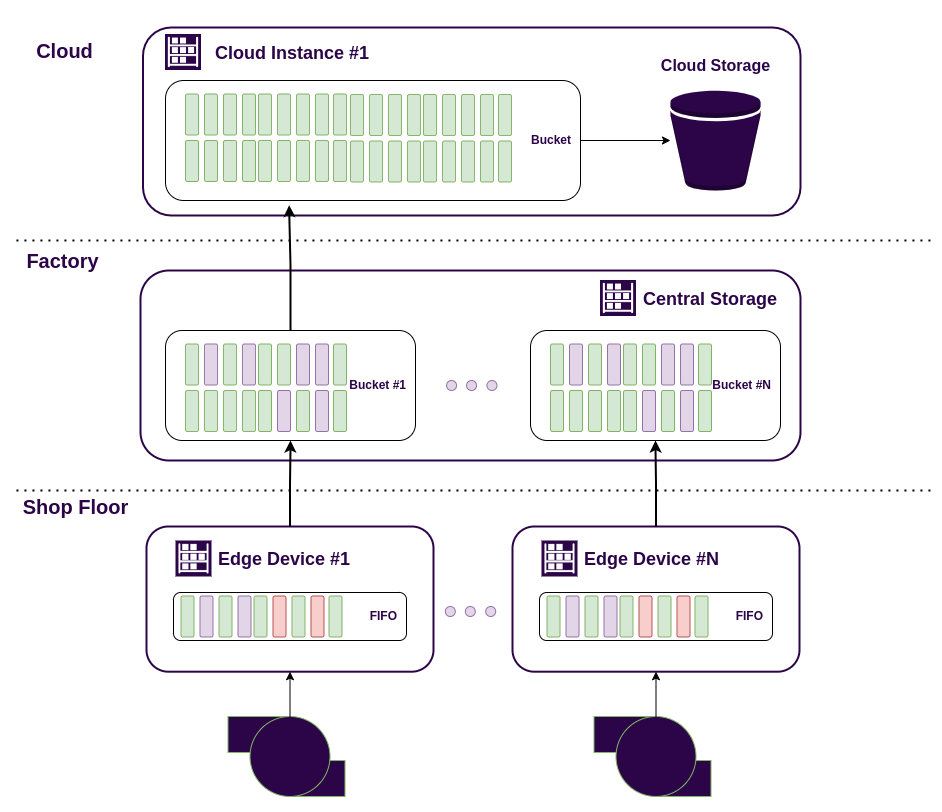

A Data Acquisition (DAQ) system collects this data, processes it, and stores it for further analysis. It typically consists of edge devices that gather real-time data, central servers or cloud storage for retention, and software that enables analytics and AI-driven insights.

An example of a 3 tier DAQ system based on ReductStore.

Traditional automation solutions like SCADA and historians are complex, expensive, and not optimized for modern cloud-based AI applications. They often limit access to data, making it difficult for engineers and data scientists to develop machine learning models and gain actionable insights.

In this article, we’ll explore the challenges of building a modern DAQ system for manufacturing and how ReductStore can simplify the process and support ELT (Extract, Load, Transform) workflows for advanced analytics and AI applications.